Products by category

Equipment Wear Parts

Construction & Civils

Construction Dozer- Construction excavator

- Construction wheel loader

- Construction Cold Planer

- Construction Surface Trencher

Quarrying & Aggregates

Quarry Dozer- Quarry excavator

- Quarry Wheel Loader

- Quarry Surface Miner

Surface & Underground Mining

Mining Dozer- Mining excavator

- Mining wheel loader

- Mining LHD Loader

- Mining Continuous Miner

- Mining Longwall Shearer

- Mining Roadheader

- Mining Surface Miner

Products by category

Equipment Attachments

Construction & Civils

Compact excavator- Construction dozer

- Construction excavator

- Construction wheel loader

Quarrying & Aggregates

Quarry Excavator- Quarry wheel loader

Surface & Underground Mining

Mining dozer- Mining excavator

- Mining wheel loader

- Mining LHD loader

Construction excavator

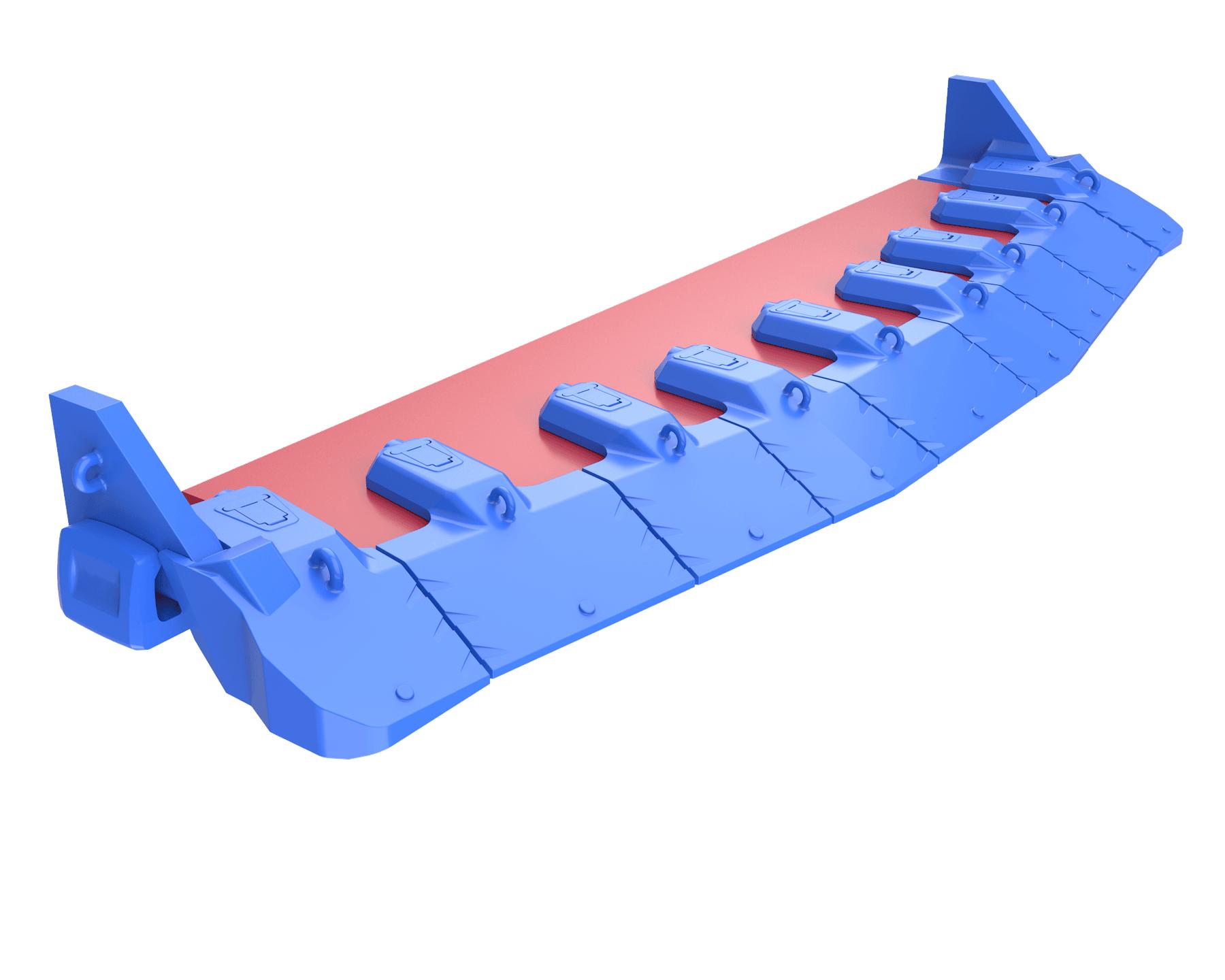

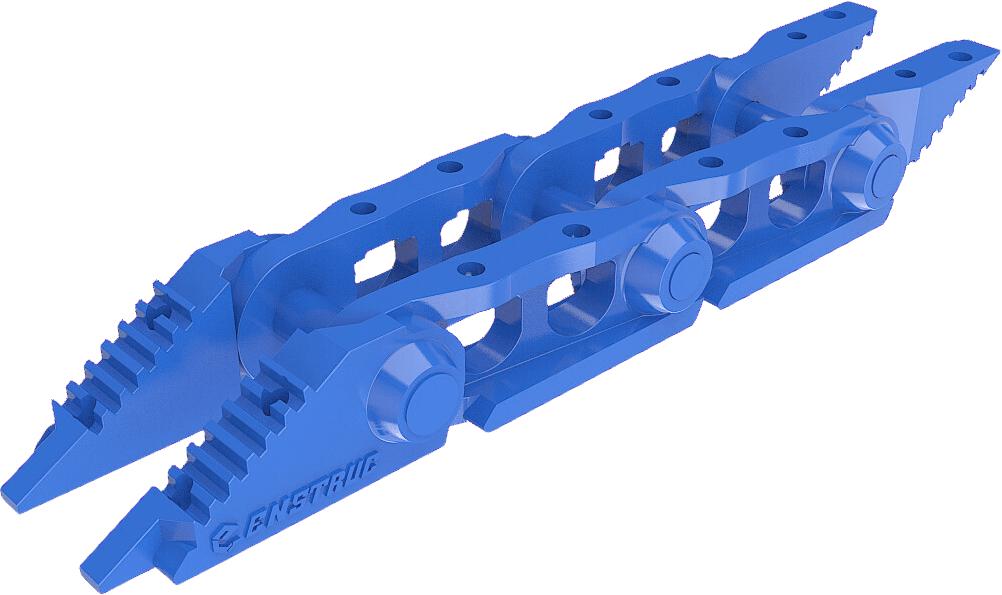

Bucket Tooth Systems

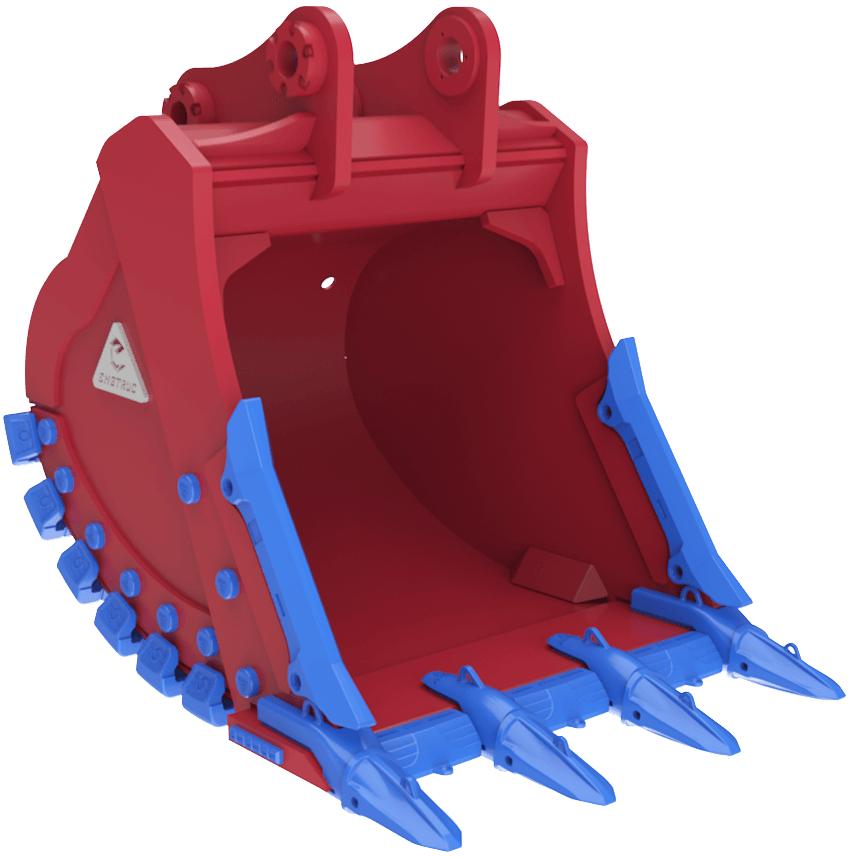

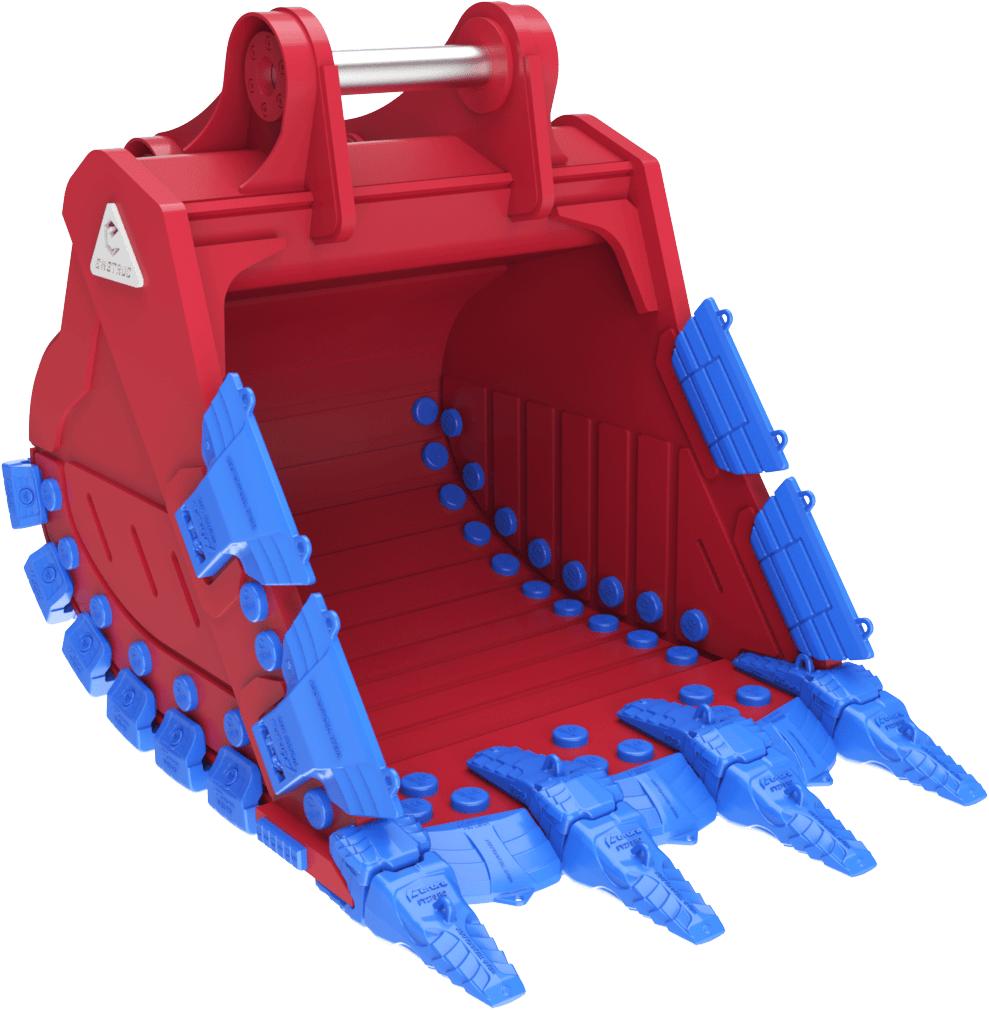

Mining excavator

Bucket Tooth Systems

Quarry excavator

Bucket Tooth Systems

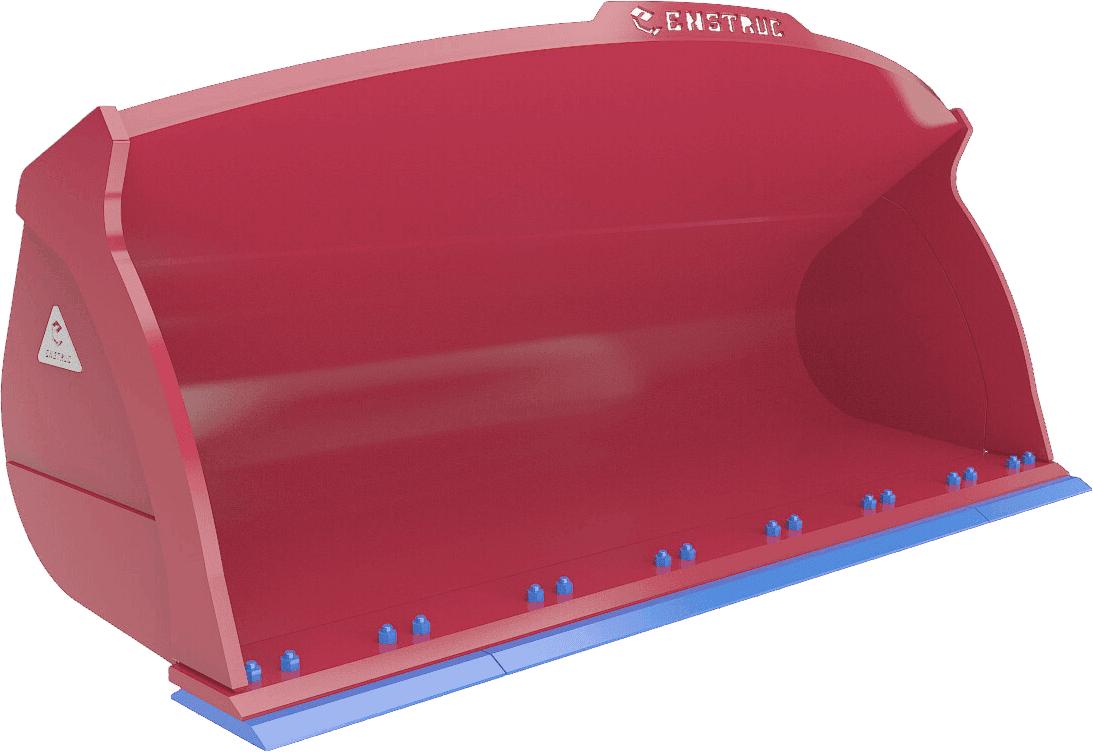

Construction wheel loader

Bucket Tooth Systems

Quarry Wheel Loader

Bucket tooth systems

Quarry Wheel Loader

Bucket wear protection

Mining excavator

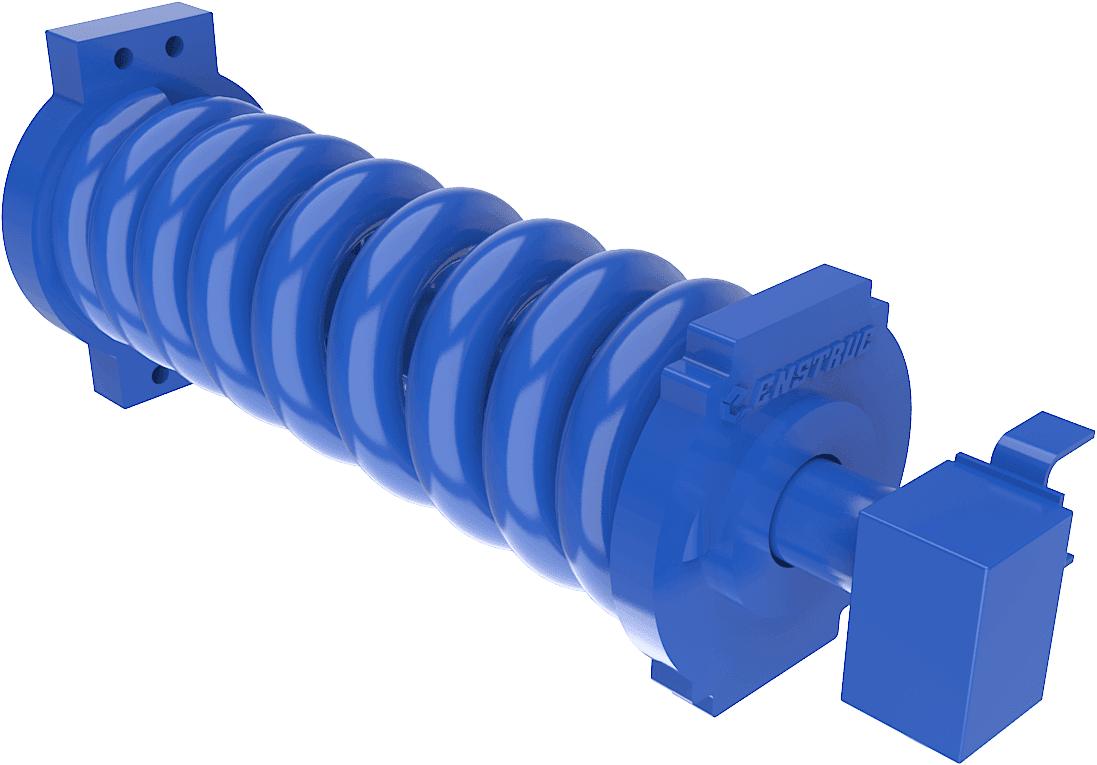

Bucket Wear Protection

Construction wheel loader

Bucket Wear Protection

Quarry excavator

Bucket wear protection

Mining wheel loader

Bucket Wear Protection

Construction excavator

Bucket Wear Protection

Product wear part

Construction excavator

Product wear part

Construction wheel loader

Product wear part

Mining excavator

Product wear part

Mining LHD Loader

Product wear part

Mining wheel loader

Product wear part

Quarry excavator

Product wear part

Quarry Wheel Loader

Mining wheel loader

Tyre Protection Chains

Construction Dozer

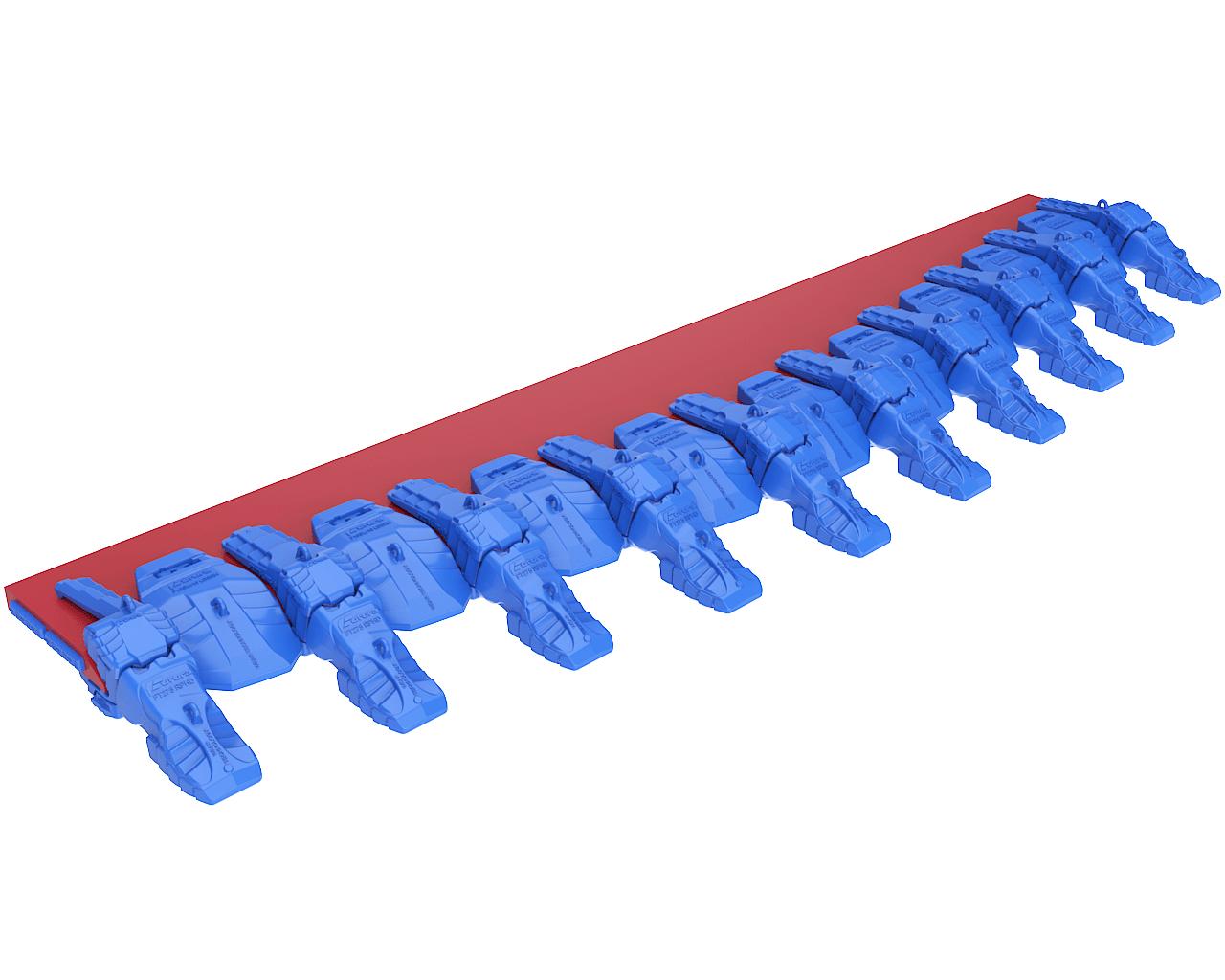

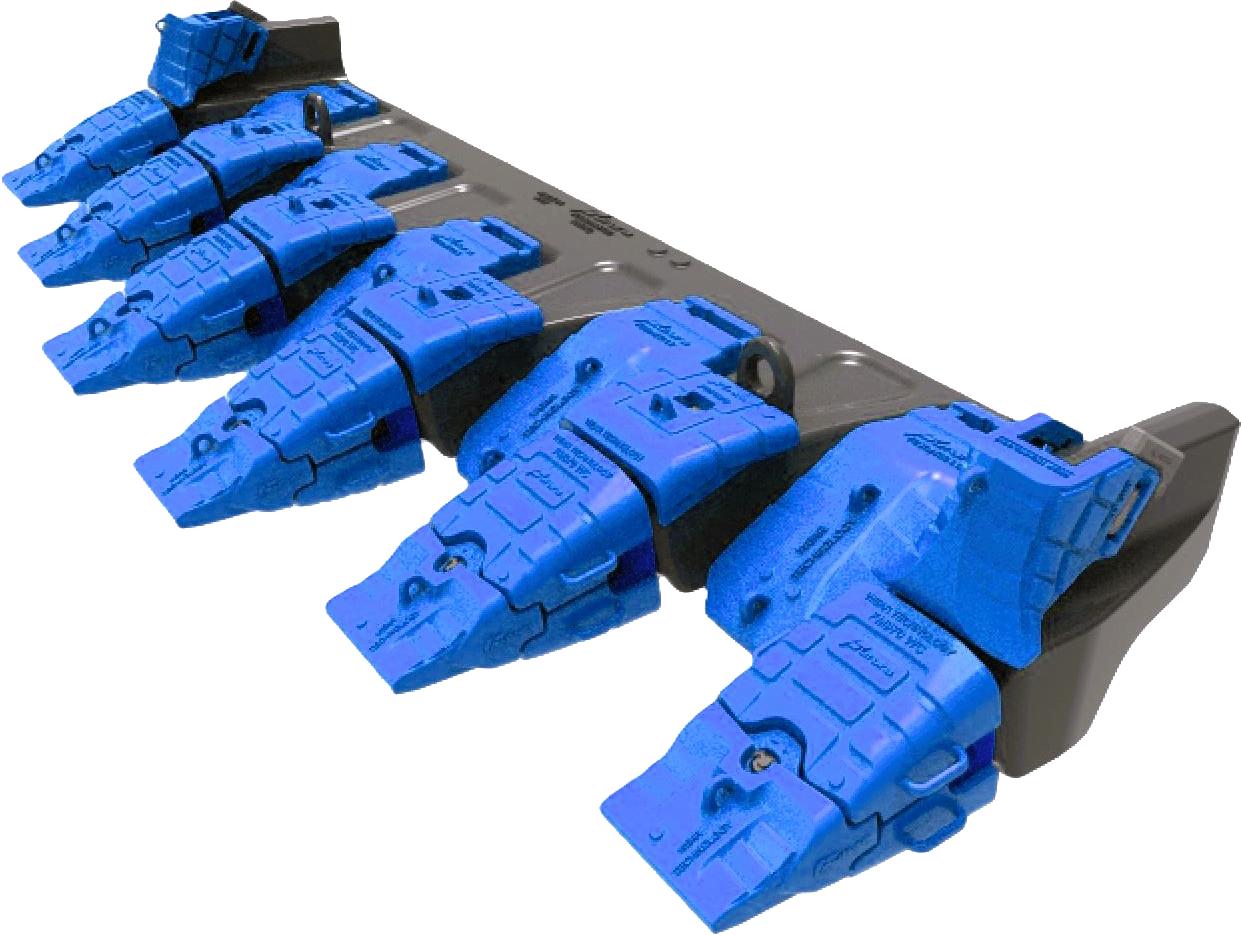

Undercarriage Parts

Mining Dozer

Undercarriage Parts

Quarry excavator

Undercarriage Parts

Construction excavator

Undercarriage Parts

Quarry Dozer

Undercarriage Parts

Mining excavator

Undercarriage Parts

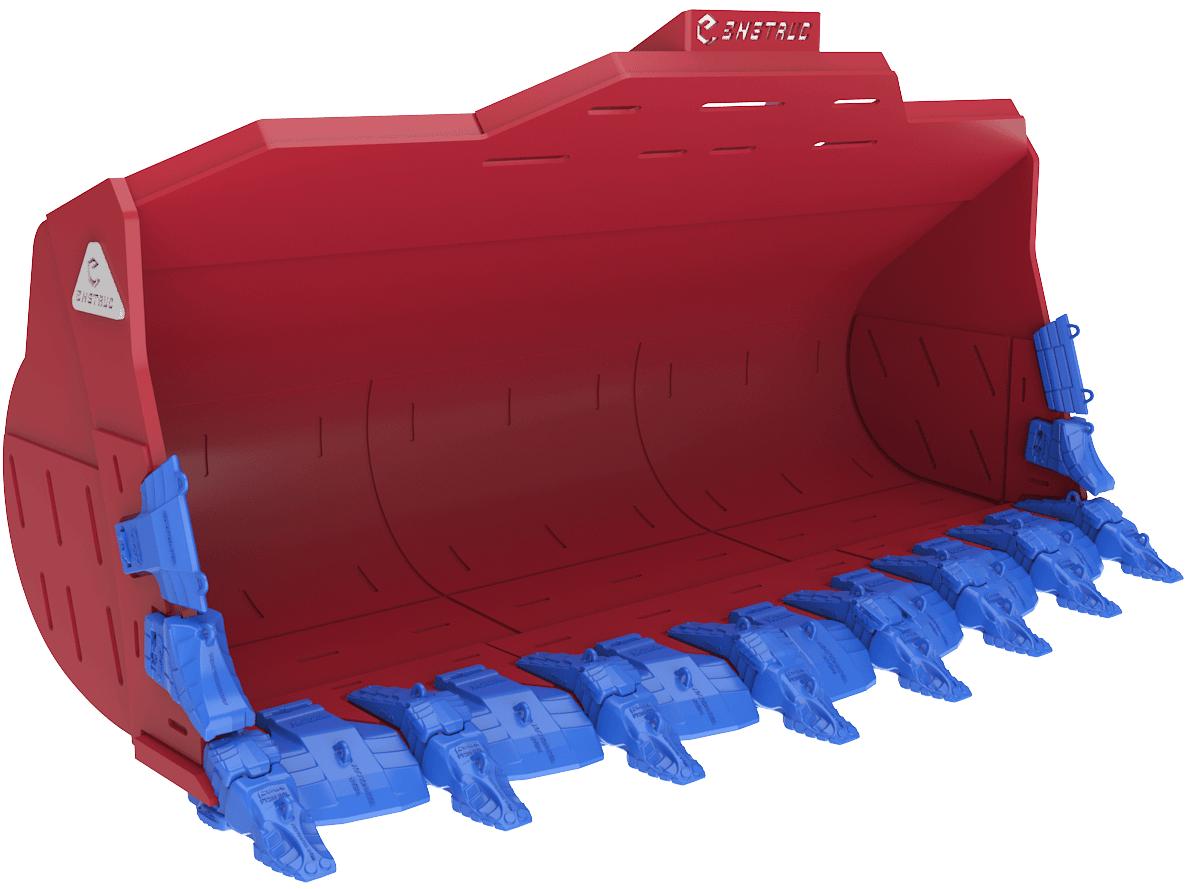

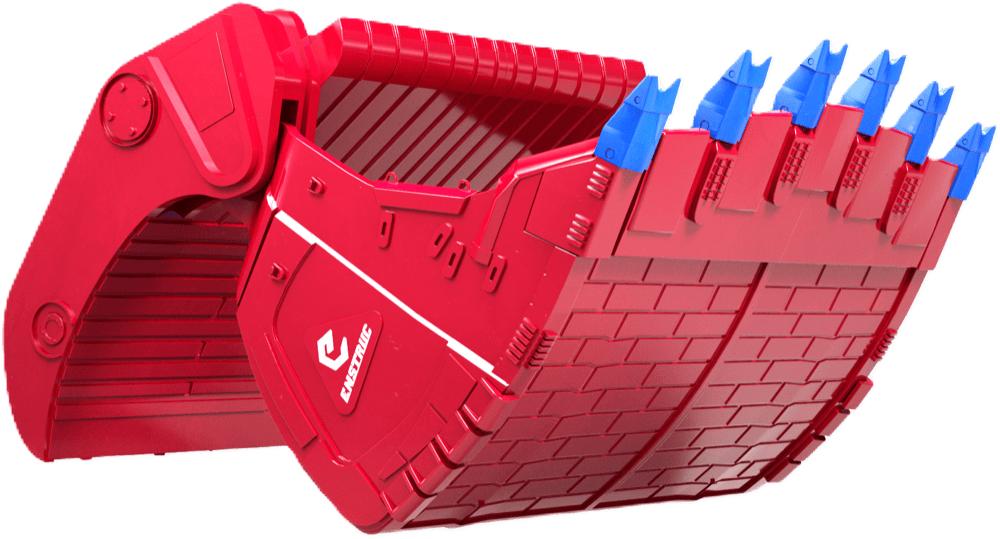

Construction excavator

Buckets

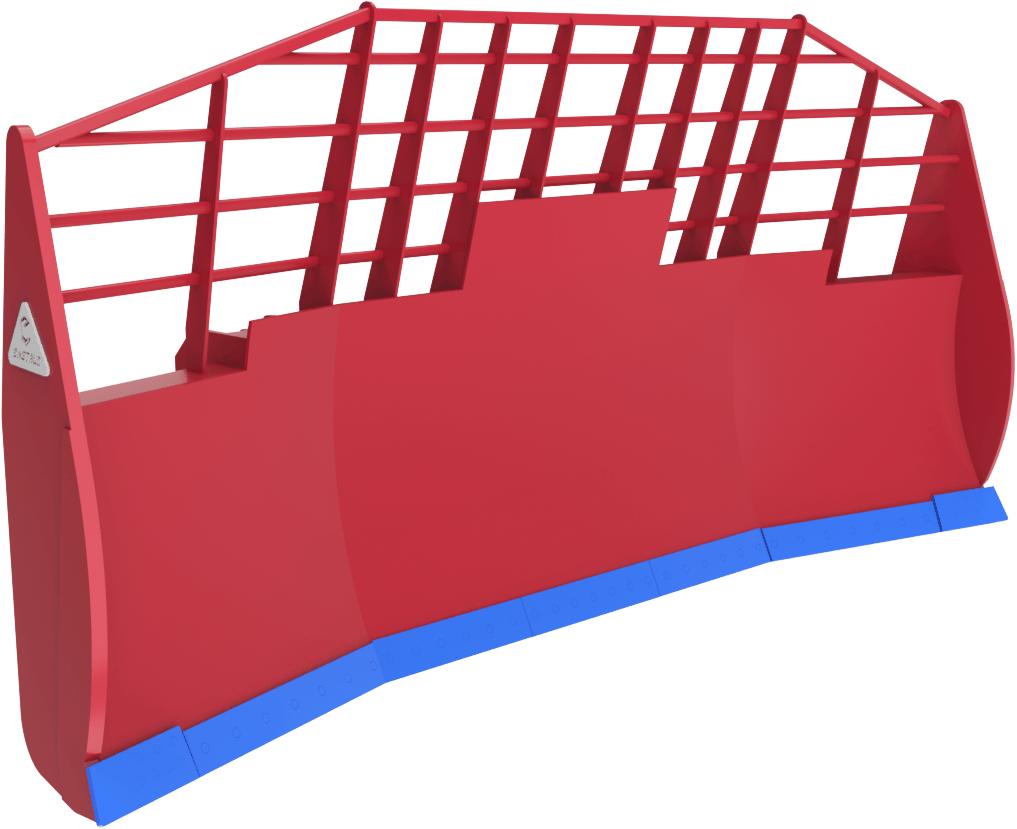

Mining wheel loader

Buckets

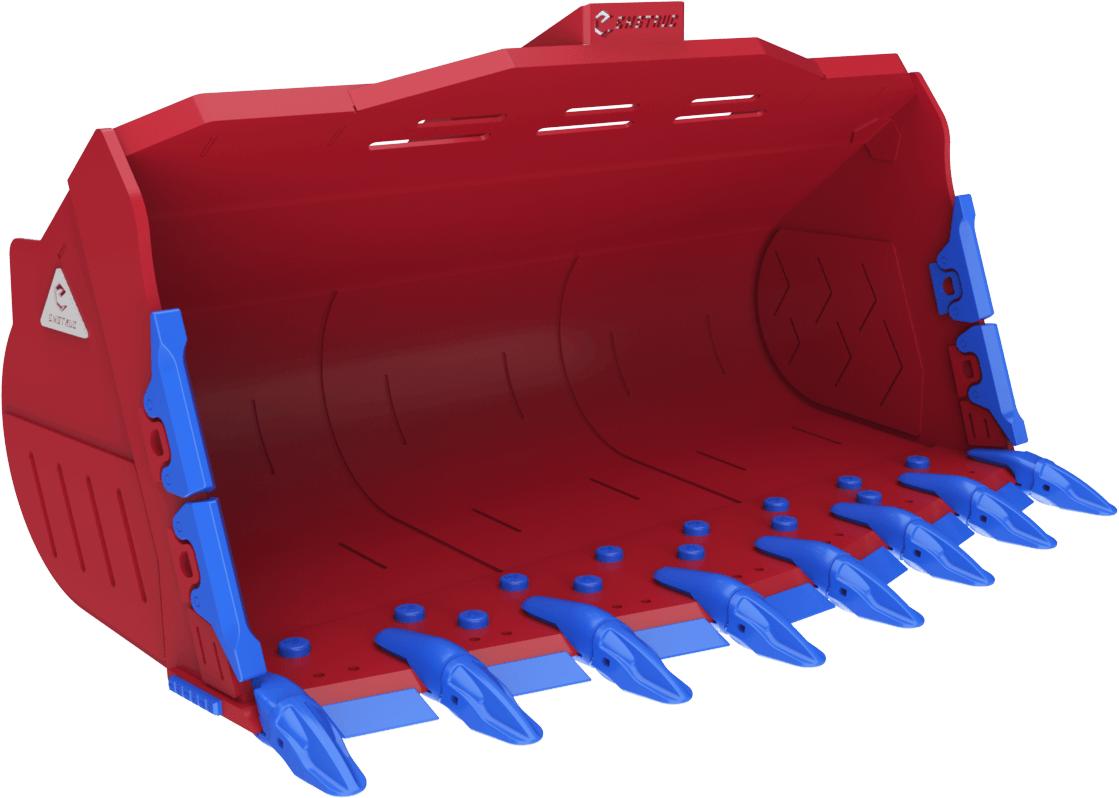

Mining excavator

Buckets

Compact excavator

Buckets

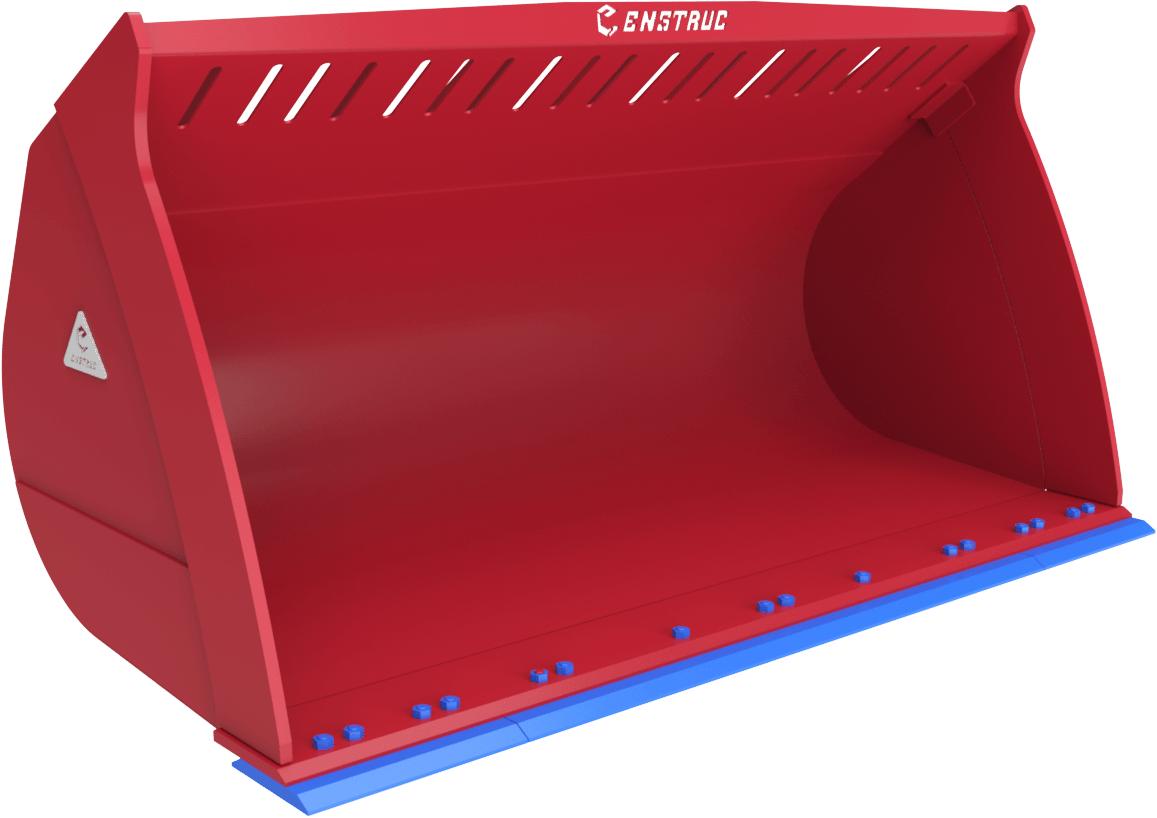

Construction wheel loader

Buckets

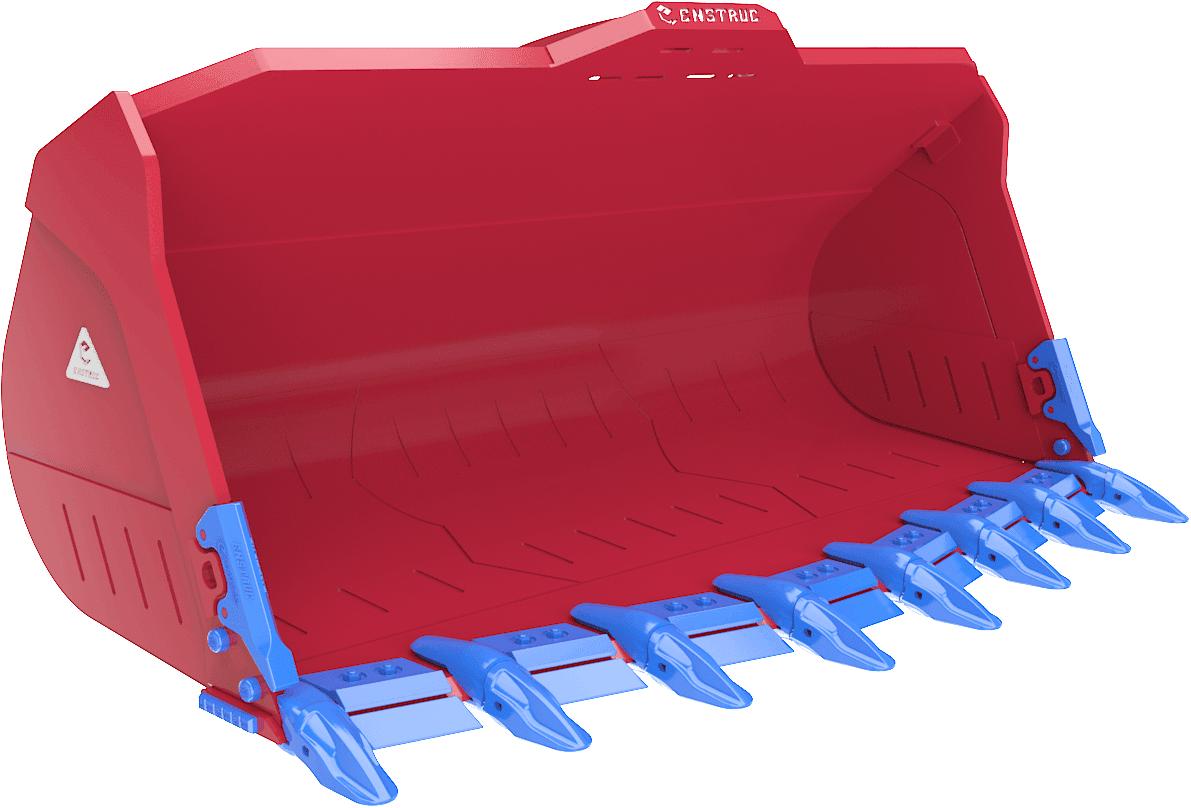

Quarry wheel loader

Buckets

Product attachment

Construction excavator

Construction excavator

Rippers